The need for creative and environmentally friendly wall materials is rising

quickly in the field of contemporary architecture.

Among these, MCM soft porcelain has emerged as a ground-breaking product for builders and architects looking for durability, flexibility, and beauty.

Being one of China's top producers of MCM soft porcelain, we create flexible wall coverings

that blend exceptional durability with organic beauty.

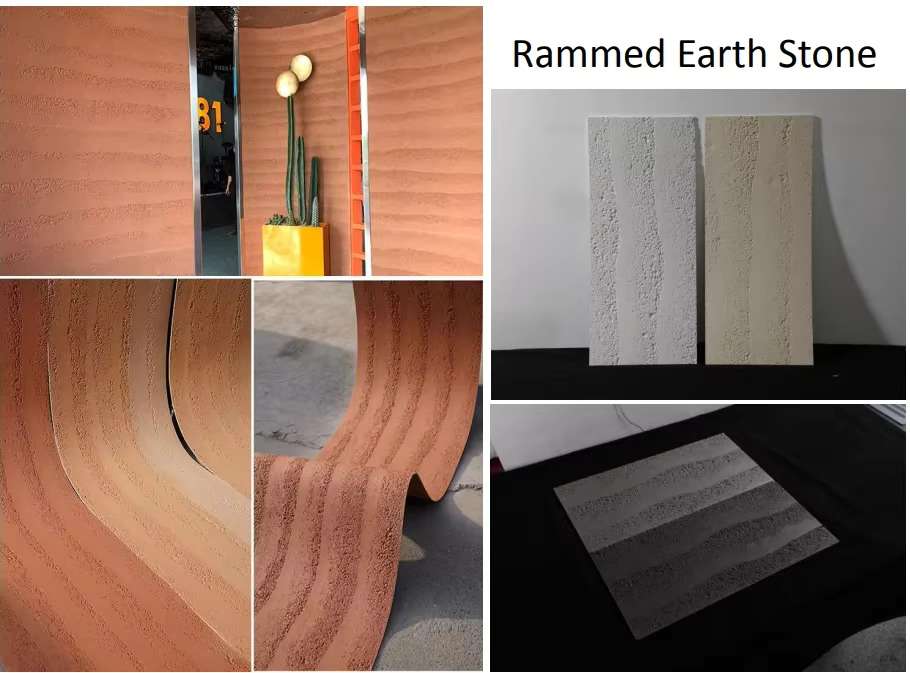

Natural clay, mineral powders, and environmentally safe polymers are used to create MCM (Modified Clay Material) soft porcelain, a flexible and environmentally friendly wall material. Although it is lighter and more elastic, it nevertheless has the appearance of classic stone or pottery.

Its unique composition makes it perfect for both exterior and interior wall cladding, particularly for curved and contemporary high-rise building designs.

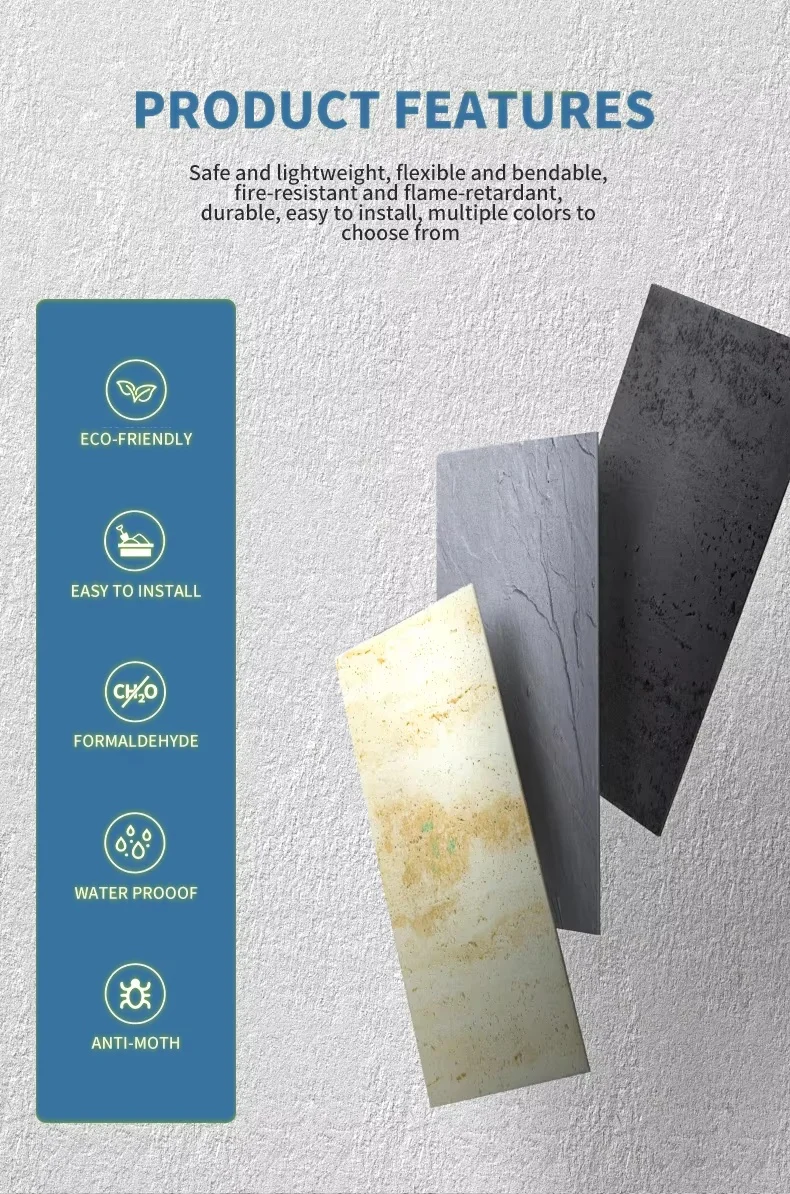

Low Water Absorption: Our products are designed to withstand moisture and cracking since they absorb less than 2% of water.

Flexibility: Soft porcelain sheets, in contrast to traditional tiles, can bend and adjust to curved surfaces, saving labor expenses and installation waste.

Lightweight and Sturdy: Even when exposed to UV light, it maintains remarkable color stability and impact resistance despite being lighter than stone.

Eco-Friendly Production: MCM soft porcelain is ideal for sustainable construction since it is produced using recyclable natural raw materials and energy-efficient procedures.

Our flexible wall coverings in bulk are perfect for:

Because of its cost-effective methods and sophisticated production technologies, China has emerged as a global center for the production of soft porcelain materials. Working with a reputable MCM soft porcelain producer in China guarantees large-scale supply, constant quality, and adaptable designs.

MCM soft porcelain is at the vanguard of the construction industry's shift toward flexible, lightweight, and sustainable materials. It is time to embrace the flexible, environmentally friendly, and long-lasting wall design of the future, whether you work as an architect, contractor, or wholesaler.

introduction The need for creative and environmentally friendly wall materials is rising quickly in the field of contemporary architecture. Among these, MCM soft porcelain has emerged as a ground-breaking product for builders and architects looking for durability, flexibility, and beauty. Being one of China's top producers of MCM soft porcelain, we create flexible wall coverings that blend exceptional durability with organic beauty. MCM Soft Porcelain: What Is It? Natural clay, mineral powders, and environmentally safe polymers are used to create MCM (Modified Clay Material) soft porcelain, a flexible and environmentally friendly wall material. Although it is lighter and more elastic, it nevertheless has the appearance of classic stone or pottery. Its unique composition makes it perfect for both exterior and interior wall cladding, particularly for curved and contemporary high-rise building designs. MCM Soft Porcelain Benefits Low Water Absorption: Our products are designed to withstand moisture and cracking since they absorb less than 2% of water. Flexibility: Soft porcelain sheets, in contrast to traditional tiles, can bend and adjust to curved surfaces, saving labor expenses and installation waste. Lightweight and Sturdy: Even when exposed to UV light, it maintains remarkable color stability and impact resistance despite being lighter than stone. Eco-Friendly Production: MCM soft porcelain is ideal for sustainable construction since it is produced using recyclable natural raw materials and energy-efficient procedures. Flexible wall covering applications Our flexible wall coverings in bulk are perfect for: Facades for homes and businesses Feature walls and interior wall design Surfaces for furniture and ceiling decoration Interiors of hotels and shops Why Opt for a Chinese MCM Soft Porcelain Manufacturer? Because of its cost-effective methods and sophisticated production technologies, China has emerged as a global center for the production of soft porcelain materials. Working with a reputable MCM soft porcelain producer in China guarantees large-scale supply, constant quality, and adaptable designs. Conclusion MCM soft porcelain is at the vanguard of the construction industry's shift toward flexible, lightweight, and sustainable materials. It is time to embrace the flexible, environmentally friendly, and long-lasting wall design of the future, whether you work as an architect, contractor, or wholesaler.

READ FULLWhen you think of porcelain, you probably imagine delicate tea sets, shiny floor tiles, or elegant bathroom fixtures. But did you know that not all porcelain is the same? Among the different types, soft porcelain material stands out for its unique texture, appearance, and composition. Whether you’re a designer, manufacturer, or just someone curious about ceramics, understanding what makes soft porcelain special can help you appreciate why it’s used in everything from fine art to luxury interiors. In this blog, we’ll break down what soft porcelain material is, explore its key properties, look at its composition and manufacturing process, and highlight its most common applications in today’s industries — all in a way that’s easy to understand. What Exactly Is Soft Porcelain Material? Soft porcelain is a type of ceramic that falls between traditional earthenware and hard porcelain in terms of hardness and firing temperature. It was first developed in Europe during the 18th century when potters tried to imitate the fine, translucent porcelain imported from China. Unlike hard porcelain, which is fired at very high temperatures (around 1,400°C), soft porcelain is fired at lower temperatures — typically between 1,200°C and 1,250°C. This difference in firing makes it slightly less hard but gives it a warmer, creamier tone and a smooth, almost silky texture that people love. Think of it as porcelain with a softer soul — still elegant and durable, but with a touch of warmth and flexibility. The Composition of Soft Porcelain Material The unique qualities of soft porcelain come down to its composition. The recipe usually includes: Kaolin (China Clay): The backbone of all porcelain types, providing whiteness and plasticity. Feldspar: Helps to form the glassy phase during firing, giving porcelain its smooth surface. Quartz (Silica): Adds strength and reduces shrinkage during firing. Bone Ash (in bone china variants): Used in some soft porcelain formulations to increase translucency and brightness. When these ingredients are mixed with water, they create a workable clay body that’s easy to shape. Once fired, the result is a material that’s slightly softer and more translucent than hard porcelain. Key Properties of Soft Porcelain Material Soft porcelain material is admired for a set of properties that make it distinct from other ceramics. Here are the most notable ones: Translucency: One of the most attractive features of soft porcelain is its ability to let light pass through. This property gives it a delicate, almost glowing appearance — ideal for decorative and lighting applications. Smooth Texture: The surface of soft porcelain is incredibly smooth, making it a favorite for high-end tableware and tiles. It has a gentle sheen that enhances its aesthetic appeal. Lower Firing Temperature: Because it’s fired at a lower temperature than hard porcelain, it consumes less energy and is sometimes more cost-effective to produce. Slightly Higher Porosity: While still denser than earthenware, soft porcelain can be more porous than hard porcelain, meaning it may absorb a small amount of water if unglazed. Warm White Color Tone: Instead of the bluish-white tone of hard porcelain, soft porcelain has a creamy, warm hue that feels more natural and inviting. Moderate Strength: It’s durable enough for regular use but can be more prone to chipping compared to its harder counterpart. How Soft Porcelain Is Made The process of making soft porcelain follows the same general steps as other types of ceramics but with subtle differences in formulation and firing. Material Preparation: The raw materials (kaolin, feldspar, quartz, and sometimes bone ash) are finely ground and mixed with water to form a smooth, plastic body. Shaping: The clay is shaped using various methods like molding, slip casting, or wheel throwing, depending on the final product. Drying: The shaped items are carefully dried to prevent cracks or warping. Firing: Soft porcelain is fired at around 1,200°C–1,250°C. This lower temperature compared to hard porcelain helps achieve the material’s signature warmth and translucency. Glazing and Second Firing (Optional): Many products are glazed and refired to create a glossy, water-resistant surface. The entire process demands precision because even slight temperature or composition variations can alter the final color, translucency, and texture. Common Uses of Soft Porcelain Material Because of its combination of beauty and function, soft porcelain material has a wide range of uses. Let’s look at some of the most common ones: 1. Tableware and Fine China Soft porcelain is often used for plates, cups, teapots, and bowls that balance elegance with usability. Its subtle translucency and warmth make meals feel more refined and cozy. 2. Decorative Art and Sculptures Artists love working with soft porcelain because it’s easier to shape and carve than hard porcelain. It’s used to create figurines, vases, and art pieces that capture fine details beautifully. 3. Tiles and Interior Surfaces Modern architects and interior designers use soft porcelain tiles for walls, floors, and backsplashes. These tiles give spaces a luxurious and polished look while maintaining practical durability. 4. Lighting Fixtures Thanks to its light-transmitting quality, soft porcelain is perfect for lamps, sconces, and diffusers that glow warmly when illuminated. 5. Sanitary Ware and Bathroom Decor Though less common than hard porcelain, some high-end bathroom accessories and décor pieces are made from soft porcelain to add a touch of sophistication. Why Choose Soft Porcelain Over Other Materials? • If you’re wondering why anyone would choose soft porcelain instead of hard porcelain or stoneware, the answer lies in aesthetics and versatility. • It offers a warmer, more organic appearance. • It’s easier to shape for intricate designs. • It creates luxurious, timeless pieces that stand out in any setting. • While it may require a bit more care due to its softer nature, the elegance it adds to interiors, dining spaces, and artwork makes it worth the choice. Conclusion To sum it up, soft porcelain material is a beautiful blend of art and science — a ceramic that’s prized for its smoothness, translucency, and natural warmth. From luxury tableware to architectural tiles, it continues to inspire creativity across industries. Its composition of kaolin, feldspar, quartz, and sometimes bone ash gives it a unique balance of strength and elegance. Whether you’re designing, manufacturing, or simply appreciating ceramics, understanding the essence of soft porcelain helps you see why it remains a timeless favorite in both traditional craftsmanship and modern design. So next time you hold a porcelain cup or walk on a porcelain tile, take a moment to admire the soft sophistication that goes into every piece.

READ FULLIf you’ve been thinking about giving your walls or floors a stylish, modern look without breaking the bank, flexible tiles are the answer. They’re lightweight, easy to handle, and perfect for DIY enthusiasts who want professional-looking results without the mess of traditional tiles. Whether you’re working on a home renovation or a commercial upgrade, flexible tiles make installation quick and stress-free. In this beginner’s guide, we’ll walk you through how to install flexible tiles step by step, along with handy tips to ensure your project turns out beautifully. What Are Flexible Tiles? Before diving into installation, let’s understand what flexible tiles are. These tiles are made from eco-friendly composite materials such as MCM (Mineral Composite Material), giving them a bendable yet durable structure. Unlike ceramic or stone tiles, they’re lightweight, crack-resistant, and can easily conform to curved or uneven surfaces. They’re commonly used for: • Wall cladding • Interior decoration • Exterior facades • Ceilings and columns The best part? You don’t need specialized tools or years of experience to install them — just a careful hand and the right adhesive. Why Choose Flexible Tiles? Flexible tiles are gaining attention in both residential and commercial design for several reasons: • Lightweight: Easier to handle than traditional tiles. • Durable: Resistant to cracking, fading, and weather changes. • Eco-Friendly: Made from sustainable, low-emission materials. • Versatile: Suitable for walls, ceilings, and even curved surfaces. • Simple Installation: Can be installed using adhesive without heavy equipment. Now that you know why they’re such a popular choice, let’s get your tools ready. Tools and Materials You’ll Need Before starting, make sure you have the following on hand: ✅ Flexible tiles ✅ Tile adhesive (recommended: polymer-based or special MCM adhesive) ✅ Notched trowel ✅ Utility knife or scissors ✅ Roller or squeegee ✅ Measuring tape and pencil ✅ Sponge or clean cloth ✅ Level or straight edge Pro Tip: Always read the manufacturer’s installation guide for any specific product recommendations. Step 1: Prepare the Surface The first step in installing flexible tiles is preparing the surface. This ensures that the tiles adhere properly and remain durable over time. • Clean the surface: Remove any dust, oil, or loose paint. • Smooth out irregularities: Use filler or putty to even out bumps or cracks. • Dry the surface completely: Moisture can affect adhesive strength. • If you’re working on a newly plastered wall, allow it to dry for at least 7 days before starting installation. Step 2: Plan Your Layout • Before applying adhesive, plan your tile layout. This step helps prevent awkward cuts or misalignment. • Measure the height and width of your wall or area. • Mark the center point both vertically and horizontally. • Dry-lay a few tiles to see how they fit — this will help you visualize spacing and pattern direction. • You can install flexible tiles in various patterns like brick bond, vertical stack, or diagonal layouts — depending on your design preference. Step 3: Apply Adhesive • Now it’s time to apply the tile adhesive. • Use a notched trowel to spread a thin, even layer on the wall. • Cover small sections at a time (about 1–2 square meters) to prevent the adhesive from drying out too soon. • Make sure the adhesive lines are uniform to ensure strong bonding. • Avoid applying too much adhesive; a thin, even coat is usually sufficient for flexible tiles. Step 4: Install the Tiles • This is the fun part — sticking the tiles to the wall! • Start from the center (or a corner, depending on your layout plan). • Press the first tile gently onto the adhesive. • Use your roller or hand to smooth out air bubbles and ensure full contact. • Continue placing the tiles side by side, pressing firmly. • Since flexible tiles are bendable, they can wrap around curved edges or uneven surfaces without breaking — just make sure to apply consistent pressure for a snug fit. Step 5: Cutting and Adjusting Tiles • You’ll likely need to trim some tiles to fit around corners, sockets, or edges. • Use a utility knife or scissors to cut flexible tiles easily. • For neat edges, measure twice before cutting. • Always check alignment as you go to maintain clean lines. • Because these tiles are soft and thin, they’re much easier to cut than ceramic or porcelain alternatives — making them ideal for beginners. Step 6: Press and Finish • Once all tiles are in place, use a roller to press them firmly against the wall or surface. This helps remove any air pockets and improves adhesion. • Wipe off any excess adhesive with a damp sponge before it dries. • Check for any misaligned pieces and adjust them immediately. • Allow the adhesive to cure as recommended by the manufacturer — usually 24 to 48 hours. Step 7: Optional Sealing • Some flexible tiles come pre-sealed, but if yours don’t, you can apply a clear sealer for added protection — especially in high-moisture areas like bathrooms or kitchens. • The sealer enhances color depth, improves stain resistance, and adds a subtle sheen to the finish. Step 8: Enjoy Your New Space • Once installation is complete, step back and admire your work! The smooth, natural texture of flexible tiles instantly elevates the look of your walls or floors, giving them a luxurious and modern touch. • And the best part? You did it yourself — no need for professional tilers or messy grout work. • Maintenance Tips for Flexible Tiles • To keep your tiles looking new for years: • Clean regularly with a soft cloth or mild detergent. • Avoid abrasive cleaners or brushes. • Check edges occasionally to ensure adhesion remains intact. • For outdoor installations, reapply a sealer every few years. Final Thoughts Installing flexible tiles is one of the easiest ways to transform any space with style and sustainability. Their bendable nature, lightweight design, and hassle-free installation make them perfect for both DIY homeowners and professional designers. With just a few tools and a little patience, you can achieve stunning results that rival traditional tilework — minus the heavy lifting. So, if you’re ready to upgrade your home’s look, flexible tiles are the smart, modern, and cost-effective way to go!

READ FULL